Chinese Lasers and 'US Standard' Wiring Myths Dispelled

Overview

There is a lot of information and opinion floating around about many Chinese lasers and the insufficient wiring and what the 'standards' actually are. We will dive into all that and more in this article

Laser Wiring 101

You probably hear that most Chinese laser engravers have 'bad' wiring and they may be unsafe to run in the US market. The reason for this is not just due to quality, etc...

Low End Lasers

Many of the Chinese lasers are designed to be run on 220V AC. The wiring is smaller in these machines because 220V means you pull half the current you would if on 110V AC. They weren't designed from the ground up to be 110V AC machines, many just use 110 components and leave the smaller wiring in place. This is why you see all the warnings about the wiring in these machines, using the integral AC outlets, etc...

Here is a typical 'ebay' Chinese laser electronics bay:

High End Lasers

Some of the high end Chinese lasers with US based distributors take in the lasers from the OEM, pull it out of the crate, rewire, and tune it up to make it suitable for the North American Market.

Thunder Laser takes a different approach. Since they design and build their lasers in-house, they wire the 110v AC machines for North America with excellent wiring harnesses and terminations, the proper gauge wire, etc... So instead the distributors having to spend all that overhead on workspace, employees, and time. Thunder can put that value back into the best quality components as well as things like dual-stage air assist and the other proprietary systems that set Thunder Laser apart. Additionally, we utilize proprietary circuit boards to autonomously control the peripherals and safety systems, but use mostly industry-standard peripherals and components for quick and painless replacement.

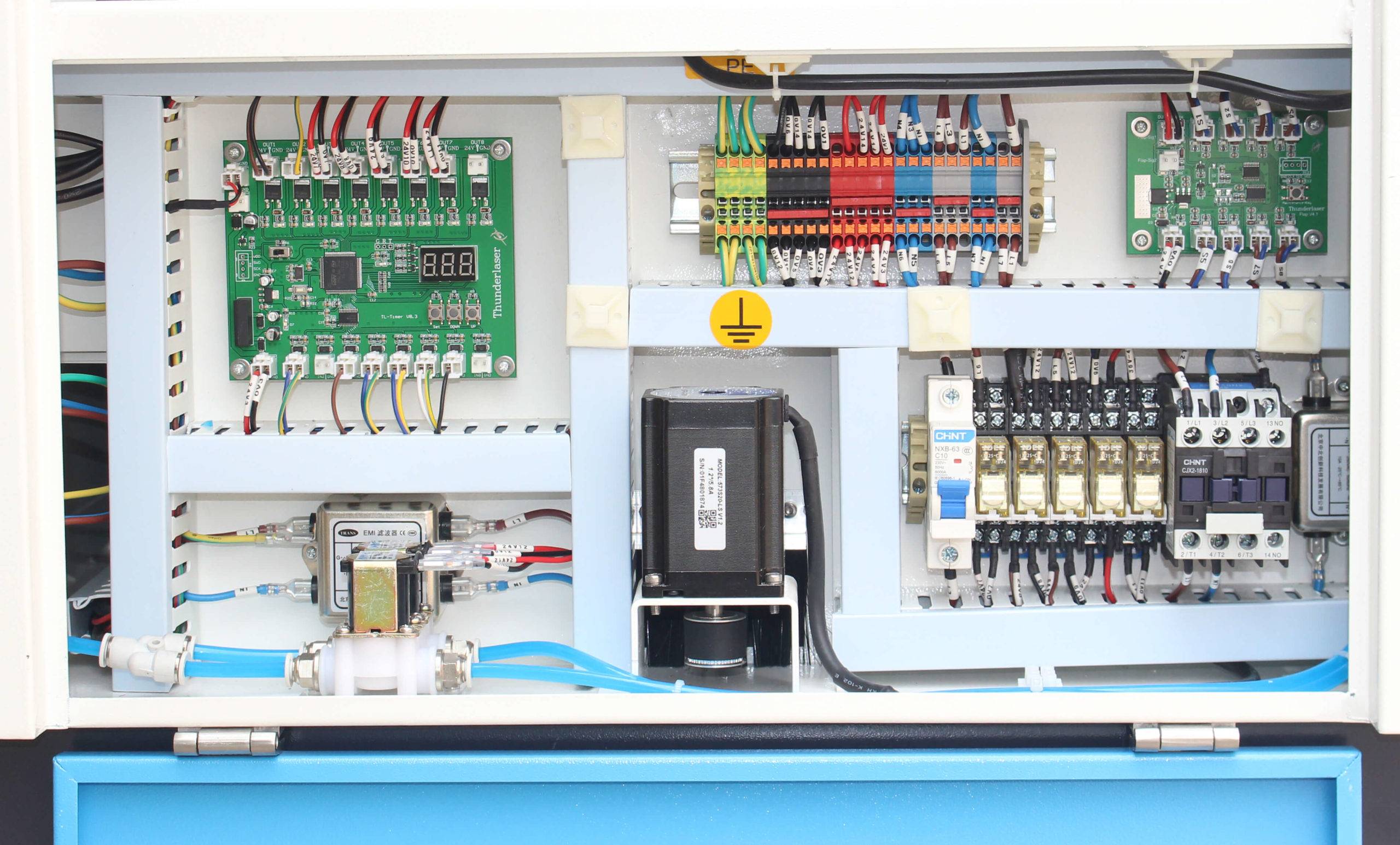

Here is what a typical Thunder Laser electronics bay looks like.

Notice that all wires are marked to make it easy to use our comprehensive diagrams and resources to locate the wiring. That is one of many Thunder advantages.

We also split the main AC power into two (2) 120v rails which are separately filtered and switched. One rail supplies only the laser power supply and the chiller via a large contactor. the other rail powers everything else so the high voltage/high current devices are not on the same rail as the electronics and other systems. More on that here: Nova Series v8 AC Power Overview and Diagnostics

Additionally, we employ an opto isolator board between the dsp and the lpsu so high voltage leakage from the lpsu doesn't feed back into the controller

US Standards

More on that here:

Related Articles

My Take On The "Big 3' High End Chinese Lasers With US Support

This is my own personal review and comparison and i tried to be as objective and accurate as possible. This was not rehearsed and i did not research first so any inaccuracies are unintentional.Thunder Laser Five Pin Rotary Port Wiring Directions and Pinout

Preface: This article covers the wiring for a 5 pin rotary based on the V5 TL Timer Wiring Schematic Wiring at Port: Port: Ruida Controller Connections: This design uses common signals with the Y Axis D2 connector Pin Designations: Pin 1 - +36V - ...Thunder Nova Plus Tl Timer V8.4 Wiring Diagram aka Schematics

Preface: These are drawings for the Nova Plus series of machines as of February 2025How to Change Bolt touchscreen Ruida GT5 to English from displaying Chinese

Preface: This article covers how to change the language back to English. If your touchscreen is not in English, do not worry. You are only a few clicks away from having it back in English. Quick Start Video: Complete Guide Step by Step: 1. Power off ...Thunder Bolt Tl Timer V9.3 Wiring Diagram September 2023 aka Schematics

See Attached

If you are a Thunder Laser USA client and still need Technical Support after exhausting the resources in the Knowledge Base, simply email support@thunderlaserusa.com and the Technical Support Team will promptly assist you! You can also use the form here.

Information contained in this Knowledgebase, on this page, in this or any other Article etc. is the property of Thunder Laser USA and shall not be copied, re-used, sold etc. Do not copy, distribute, or reproduce without express written permission from Thunder Laser USA.