Rotary Axis no motion troubleshooting

Preface: This guide will walk you through determining a possible reason as to why your rotary will not spin and is applicable to Nova, Bolt and Odin series machine. If you complete this guide without a definitive cause, please email support@thunderlaserusa.com and summarize what you completed.

Before we begin:

The Thunder Laser Machines will operate a rotary different than other brand machines. We currently use a 7 Pin connector that tells the Ruida controller when a rotary is plugged in and when the rotary should be powered.

First things to check:

This will be some of the easier things to check that may be the cause.

Check the Rotary Cable Connector

Check for bent pins or pins that have retracted. If the pin is slightly bent, bend it back in place and try to plug in.

If you are unable to resolve, send a picture of the connector pins to support@thunderlaserusa.com

Check the Dip Switch Settings

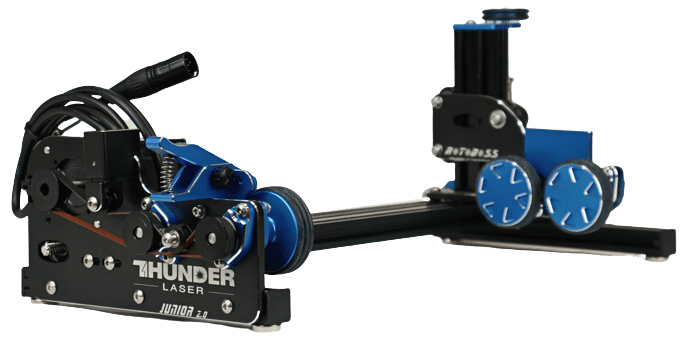

The driver is located on the Rotary, it is integrated into the motor. Look for the blue area with the little white switches on it.

Rotoboss Low/Junior/Boss | Rotoboss Talon | Rotoboss Talon Pro |

*Dip Switch #5 controls the Clockwise and Counter Clockwise rotation of the motor. If your rotary needs to be reversed, unplug it, swap the position of Dip Switch #5 and plug it back in and test.

Verify that your rotary settings are in range in Lightburn

In Lightburn, Open up the Rotary Setup menu and verify that the settings are read from the machine and that they are within normal values:

If the steps are set to 360....definitely an issue. The values will depend on which rotary you have.

Jog the rotary from the Machine

Try to jog the rotary U Axis from the machine controller after updating Steps and Roller Diameter.

Older Ruida Screen | Newer Ruida Touch Screen |

To jog, press the MENU button on the controller, scroll to "U move" and then use the left and right arrows to jog to rotary. | Use the physical buttons at the bottom of the screen or go to the MANUAL tab, unlock the nudge buttons and use the soft keys to jog the rotary (You may need to adjust your nudge value, as shown is 100mm) |

Bolt Screen Rotary Indicator

On your Bolt series machine, check for this indicator to let you know that the machine sees that a rotary is plugged in.

Power Verification Steps:

Power on the machine. This guide assumes that the 36V power supply is working if the X, Y and Z axis (The laser head and honeycomb bed) are able to move around.

Check for Green Power Status LED

On the rotary motor Driver, look for the green power LED to be illuminated.

Rotary Unplugged from Machine | Rotary Plugged into the Machine |

Green LED is for PWR not illuminated | Green LED for PWR is Illuminated |

If the Green LED is off, the go to the next step in this section

Check for the Power Relay Activation: Nova Series

Open the lower blue door(s) on the right hand side of your machine to find the relays.

There are 5 relays, the rotary is the furthest to the right

Rotary Unplugged from the Machine | Rotary Plugged into the Machine |

If the Green LED is on, then the relay is activating. Power off the machine and check the tightness of the terminations at the top of the relay. If that does not fix it then email support@thunderlaserusa.com with a summary of what you have completed

If the Green LED is off, the go to the next step in this section

Check for the Power Relay Activation: Odin Series

Open the left side door on your machine to find the relays.

There are 5 relays, the rotary is the furthest to the right

Rotary Unplugged from the Machine | Rotary Plugged into the Machine |

If the Green LED is on, then the relay is activating. Power off the machine and check the tightness of the terminations at the top of the relay. If that does not fix it then email support@thunderlaserusa.com with a summary of what you have completed

If the Green LED is off, the go to the next step in this section

Check for the Power Relay Activation: Bolt Series

There are 4 relays. The rotary relay is 2nd from the top.

Rotary Unplugged from the Machine | Rotary Plugged into the Machine |

If the Green LED is on, then the relay is activating. Power off the machine and check the tightness of the terminations at the top of the relay. If that does not fix it then email support@thunderlaserusa.com with a summary of what you have completed

If the Green LED is off, the go to the next step in this section

Check TL Timer Input\Output Operation: Nova\Odin Series

This is for the Nova/Odin Series with 8.xx TL Timer. The output will be Channel 7 with wire OV11.

Rotary Unplugged from the Machine | Rotary Plugged into the Machine |

If the Red LED is on, then check the tightness of the connections on the bottom of the relay in the above step. If the Red LED is still off off after tightening the connections, then try this

Check TL Timer Input\Output Operation: Bolt Series

This is for the Bolts Series with 9.xx TL Timer. The output will be Channel 7 with wire OV9. The input from the Ruida controller comes to the TL Timer through the RTlink

Channel 7 LED OFF | Channel 7 LED ON |

If the Red LED is on, then check the tightness of the connections on the bottom of the relay in the above step. If the Red LED is still off off after tightening the connections, then try this

Manually Activate Rotary Relay

4. Use TL Timer to Manually Turn on the Rotary

Use this article to set the TL Timer board to turn on Channel 7 which should energize the Red LED for OUT7, Energize the Relay to provide power to the Rotary Socket and then will Turn on the Green LED on the Rotary Driver like what was mentioned in above sections. (rotary must be plugged into the machine)

Please email support@thunderlaserusa.com with a summary of what you have completed.

Simulate Pin6 and Pin7 of Rotary Cable

Bend a paper clip so that the legs are the same length. Insert into the machine rotary port as shown into Pins 6 and 7. Check that the Rotary Relay and TL timer LED's light up. If this is the case, then most likely your Rotary Cable has a broken Pin6 to Pin7 connection internally that needs to be replaced.

Control Signals Checks:

This section will check some of the signals that go between the Ruida Controller and TL Timer

Rotary Cable Pin6 and Pin7

On the rotary connector, Pin 6 and Pin 7 should be tied together internally. This connection can fail so we need to check it.

Using a multimeter, check the OHMs to be under 2 OHM or for the audible continuity signal that pins 6 and 7 are jumpered together.

If Pins 6 and 7 are jumpered (Low Ohms, Beep from meter), goto the next step in this section

If Pins 6 and 7 are not jumpered, please email support@thunderlaserusa.com with a summary of what you have completed.

Ruida Controller to TL Timer

Lets check the Ruida input for rotary connection active on IN1 on the Ruida Controller Connector CN2

Unplug CN2 from the Controller:

Unplug this connector from the TL timer Board for TL Timer Input 7:

Use a multimeter to measure the continuity between IN1 and GND on the green Ruida Connector.

Rotary Unplugged:

CN2 connector PIN IN1 to CN2 Connector GND - Open

Rotary Plugged into the Machine:

CN2 connector PIN IN1 to CN2 Connector GND - Continuity, low Ohms, Audible tone on multimeter if selected

If the IN1 to GND Shows continuity, then proceed to the next step of "Last thing to check".

If the IN1 to GND Shows open, then email support@thunderlaserusa.com with a summary of what you have completed.

Last thing to check

Ok so this is a short blurb but the amount of work is not as short:

Inspect the wiring of all the plugs\connectors\devices mentioned in the article above. Visually inspect that the wire ferrules\crimps are on the wire conductor and not the wire insulation. Make sure screw terminals are tight.

Plug everything back in when you are done testing.

Bypass Method for Faulty Pins 6 and 7 on Rotary Cable:

In order to force the Laser Ruida Controller to run in Rotary Mode and to get the TL Timer to provide power to the rotary, we can install a jumper wire between GND and IN1 on CN2 of the Ruida controller as shown by the Red Line on the image below. Power off the machine while installing the jumper. Plug CN2 and the rotary back in for use.

Note: In order to run a normal non rotary job, you must remove the Jumper wire. The Jumper Wire must only be in place when you want to run a rotary job.

Useful graphics and links:

Below are some useful graphics and links that are compiled here because they may be helpful as you troubleshoot.

Connector Pinout

Port Pinout

Interface Wiring

Connector Pinout

This is the connector on the rotary cable.

Port Pinout

This is the port on the laser machine.

Interface Wiring

This is a simplified drawing for Nova and Odin Series Machines Rotary Wiring for 7 Pin XLR (Trimmed down from the main schematics)

(note that the pinout is shown for the Cable End, likewise from the rear of the Port)

Rotary Port to Ruida Controller | TL Timer to Power Relay |

Related Articles

Nova Series Y Axis Motion Failure

Preface: This article will cover reasons why your Y axis will not move front to back. There can be several different causes from mechanical to electrical, including a failed sensor, failed driver, improper adjustment, belt tension etc. The only way ...RotoBoss Roller Rotary Setup

Preface: This Article covers how to set up the rotary to get your steps right for a given tumbler and some best practices. This article is relevant for Thunder Laser Gantry style Lasers with Ruida Controllers. The information contained in here is not ...X, Y and Z Honeycomb Axes will not move when Roller Rotary is plugged in and Rotary will not Spin

This article describes the situation where when the Roller Rotary is plugged in, the X, Y and Z (Honeycomb) Axes will not move and the rotary will not spin. Other Articles of interest: Thunder 7 Pin XLR Rotary Port Rotary Axis no motion ...Nova Series X Axis Motion Failure

Preface: This article will cover reasons why your X axis will not move left or right. There can be several different causes from mechanical to electrical, including a failed sensor, failed driver, improper adjustment, belt tension etc. The only way ...Z Axis Motion Control Changes

For the Z axis, we gradually changed the Z axis motion system to only one bigger motor for Nova 35\51\63 instead of two. Because according to customers' experience, two motors on Z axis makes the motorized table out of level. And after testing, the ...

If you are a Thunder Laser USA client and still need Technical Support after exhausting the resources in the Knowledge Base, simply email support@thunderlaserusa.com and the Technical Support Team will promptly assist you! You can also use the form here.

Information contained in this Knowledgebase, on this page, in this or any other Article etc. is the property of Thunder Laser USA and shall not be copied, re-used, sold etc. Do not copy, distribute, or reproduce without express written permission from Thunder Laser USA.