Thunder Laser Nova Series: Focal Ramp Test

Lenses, Usage and Ramp Test

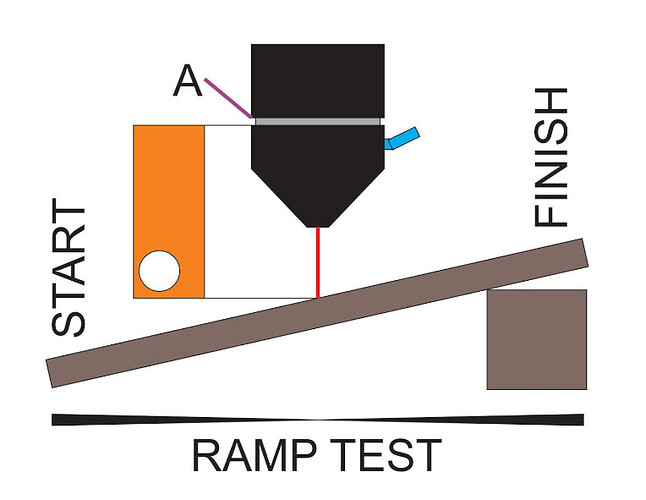

Focal Ramp Test.

Finding the perfect focal point (smallest dot size) can be difficult. Many lenses have a threshold or manufacturing tolerance that can vary up to 2-3mm.

Take a standard 2" lens for example, it's possible that this lens's "perfect" focal point is between 4-6mm. For most people this variable goes unnoticed.

Typical engraving of vectors and normal cutting will not show this disparity. But when we start pushing our laser to the limit with fine cutting, inlays and

photos every dot or the smallest dot can drastically change your result. Check out the videos and photos below that better detail this process and how to

fine tune your focal distance.

Image below was sourced from Lightburns user forum.

This video by Maverick CNC is an excellent depiction of the ramp test. One thing to note, on the Thunder Nova/Odin we can use the

right/left move arrows on the controller with the pulse button, meaning no need to design a file in Lightburn.

Here is a video by one of our users who, after testing, found great results!

Related Articles

The Usual Suspects and Preparing For Your 1 Hr. Training

Preface: The Usual Suspects are the things that most commonly get overlooked or are incorrect that can burn up training time on things that should already be checked and if not mastered. If you choose to not follow this guide you will likely ...Tuning The Focal Length on The Stock 2" Head

This documentation is specific to the Thunder Nova series stock 2" (50.8mm) focal length lens assembly. We have typically used 6mm (1/4") as the reference for focus but it can vary. Thunder Laser actually specifies the focal distance as 4.5mm~6.5mm: ...Thunder Bolt Pro 22 and Pro 32 Series Unified Manual

LightBurn Material Test File

Preface: The article covers some pre-made material test cards and the built in Lightburn Material Test Generator for CO2 lasers like the Thunder Laser Bolt, ODIN and Nova machines Quick Start Videos: Thunder Material Test Lightburn Material Test ...Legacy Lightburn Material Test File

Preface: The article covers some pre-made material test cards and the built in Lightburn Material Test Generator for CO2 lasers like the Thunder Laser Bolt, ODIN and Nova machines Quick Start Videos: Legacy Material Test Cards Lightburn Material Test ...

If you are a Thunder Laser USA client and still need Technical Support after exhausting the resources in the Knowledge Base, simply email support@thunderlaserusa.com and the Technical Support Team will promptly assist you! You can also use the form here.

Information contained in this Knowledgebase, on this page, in this or any other Article etc. is the property of Thunder Laser USA and shall not be copied, re-used, sold etc. Do not copy, distribute, or reproduce without express written permission from Thunder Laser USA.